Anionic Polymer

TianFloc's anionic powders range from low to very high molecular weight, low charge to very high charge and are a premium product suitable for all types of industrial treatment regardless of your industry. |

| Product Name | Appearance | Molecular Weight | Charge Density | Applications |

| TIANFLOC® A245 | Powder | Medium | Low | Mining, water treatment |

| TIANFLOC® A245L | Powder | Medium | Low | Mining, potable water |

| TIANFLOC® A456L | Powder | Medium | Medium | Mining, water treatment |

| TIANFLOC® A556L | Powder | High | Medium | Mining, water treatment |

| TIANFLOC® A656L | Powder | High | Medium | Mining, water treatment |

| TIANFLOC® A756 | Powder | High | High | Mining, water treatment |

| TIANFLOC® A878 | Powder | High | High | Mining, water treatment |

Cationic Polymer

| Product Name | Appearance | Molecular Weight | Charge Density | Applications |

| TIANFLOC® C1205 | Powder | Medium | Low | Water treatment, sludge dewatering |

| TIANFLOC® C1210 | Powder | Medium | Low | Water treatment, sludge dewatering |

| TIANFLOC® C1215 | Powder | High | Low | Water treatment, sludge dewatering |

| TIANFLOC® C1220 | Powder | High | Medium | Water treatment, sludge dewatering |

| TIANFLOC® C1240 | Powder | High | Medium | Water treatment, sludge dewatering |

| TIANFLOC® C1260 | Powder | High | High | Water treatment, sludge dewatering |

| TIANFLOC® C1280 | Powder | High | High | Water treatment, sludge dewatering |

| TIANFLOC® C1290 | Powder | High | Ultra High | Water treatment, sludge dewatering |

Non-ionic Polymer

| Product Name | Appearance | Molecular Weight | Charge Density | Applications |

| TIANFLOC® N100 | Powder | Medium | Ultra Low | Water treatment, mining |

| TIANFLOC® N134 | Powder | High | Low | Water treatment, mining |

Fracking

| Product Name | Appearance | Molecular Weight | Charge Density | Applications |

| TIANFLOC® A689EOR | Powder | Ultra High | Medium | Our flagship polymer |

| TIANFLOC® E3025 | Powder | Ultra High | Medium | Low AMPS co-polymer |

| TIANFLOC® AB1000 | Powder | Medium | Low | High AMPS co-polymer |

Enhanced Oil Recovery

| Product Name | Appearance | Molecular Weight | Charge Density | Applications |

| TIANFLOC® A245EOR | Powder | Medium | Low | |

| TIANFLOC® A345EOR | Powder | Medium | Low | |

| TIANFLOC® A634EOR | Powder | Medium | Medium | |

| TIANFLOC® A656S | Powder | High | Medium | SNF FP 3630 |

| TIANFLOC® A767T | Powder | High | High | Injected at CNRL and Cenovus in Canada |

| TIANFLOC® A689EOR | Powder | Ultra High | Medium | Our flagship polymer |

| TIANFLOC® E3025 | Powder | Ultra High | Medium | Low AMPS co-polymer |

| TIANFLOC® AB1000 | Powder | Medium | Low | High AMPS co-polymer |

PLA (Polylactic Acid Fibre) Ultra-Short Fibre

Ingredients : 100% PLA

Specifications :1.50dtex×6mm

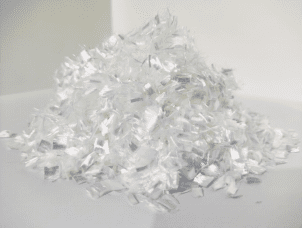

Appearance : White fiber

Characteristics : Biodegradable, Easily dispersed

PLA (Polylactic Acid Fibre) Ultra-Short Fibre

Ingredients : 100% PLA

Specifications :1.50dtex×6mm

Appearance : White fiber

Characteristics : Biodegradable, Easily dispersed

Item | Test Results | Item | Test Results |

Linear Density (dtex) | 1.48 | Extra Long Fiber Rate(%) | 0 |

Linear Density Deviation Rate(%) | -1.33 | Double Length Fiber content(mg/100g) | 0 |

Breaking Strength (CN/dtex) | 3.99 | Defect Content(mg/100g) | 0 |

Elongation at Break(%) | 30.8 | Oil Content ( MeOH )(%) | 0.21 |

Short Fiber Length(mm) | 5.90 | Moisture Regain(%) | 3.40 |

Length Deviation Rate(%) | -1.67 | Shrinkage Ratio(130℃ 15min)(%) | 6.53 |

Fiber is added to the fracturing fluid to form fiber fracturing fluid. The fibers prevent proppant flowback at fracture ports by mixing the fibers with the proppant (sand) and dispersing the fibers within the proppant into a three-dimensional network that binds the proppant and prevents it from moving.

Adding fiber to the sand-carrier improves the sand-carrying capacity of the fluid and carrying power of proppant, which enables the proppant to be transported farther to form longer hydraulic fractures and helps control the height of the proppant settlement, thereby enhancing the control of fracture height during fracturing.